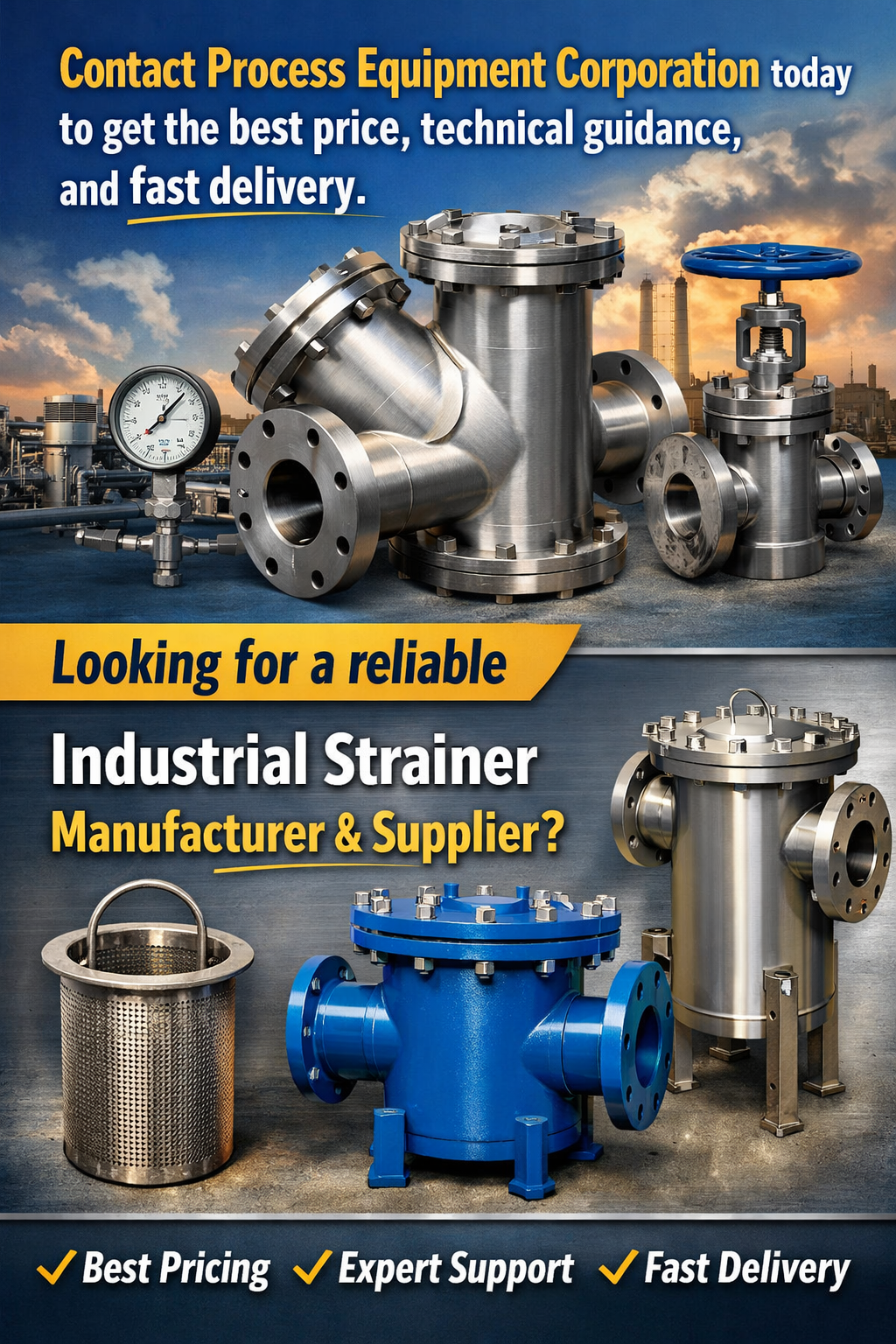

Get High-Quality Bucket Strainer in Soweto

Basket Type Strainer in Soweto is designed to provide reliable filtration for pipelines handling liquids, chemicals, and industrial fluids. Manufactured with durable materials and a robust basket element, it effectively removes debris, protects pumps and valves, and ensures smooth system performance. Ideal for oil & gas, water treatment, and process industries, our basket strainers deliver long-lasting efficiency and easy maintenance for demanding industrial applications in Soweto.